Who is BBMold for?

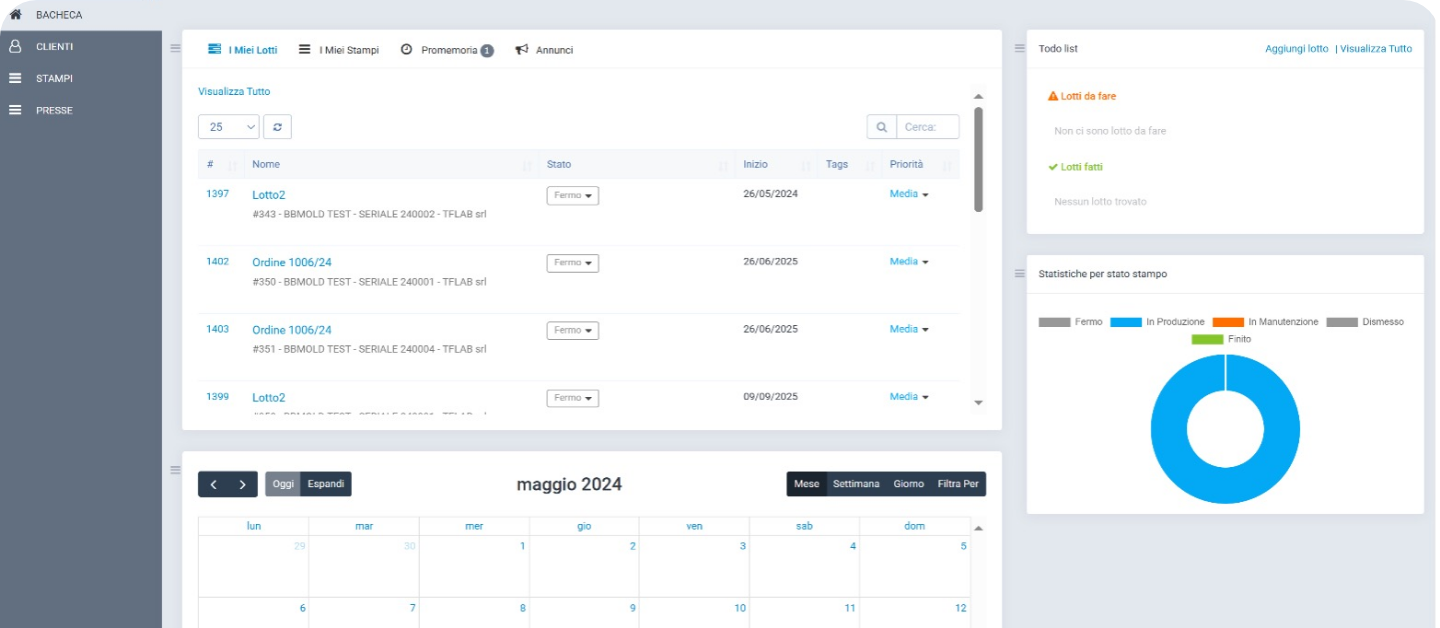

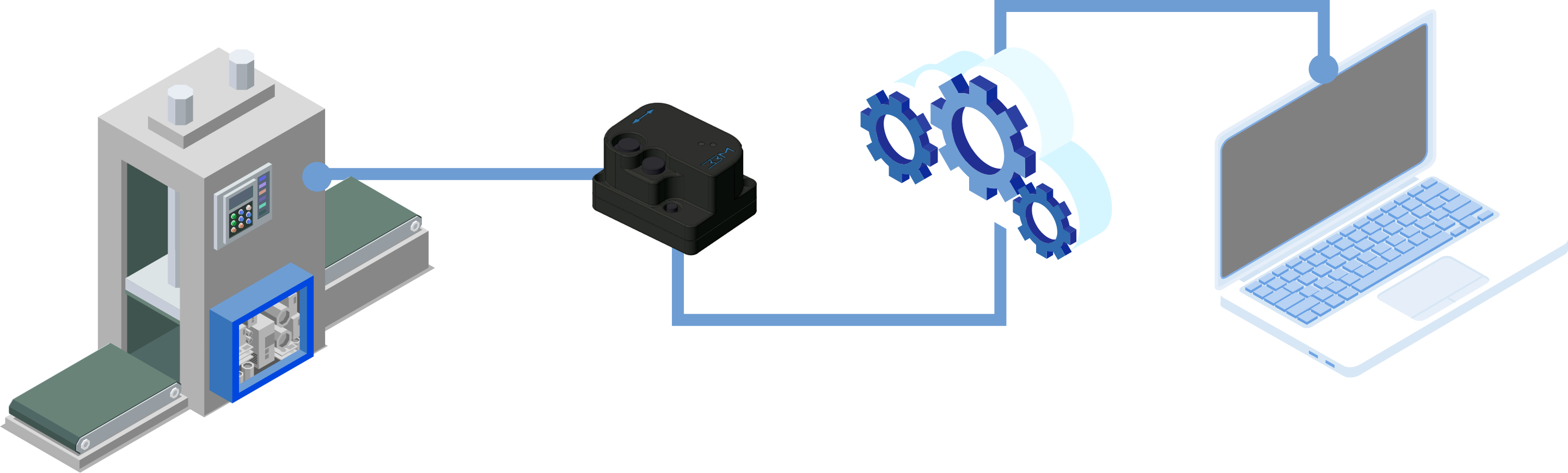

BBMold is the ideal solution for those who need to monitor the activity of their molds spread around different production sites without manual entries.

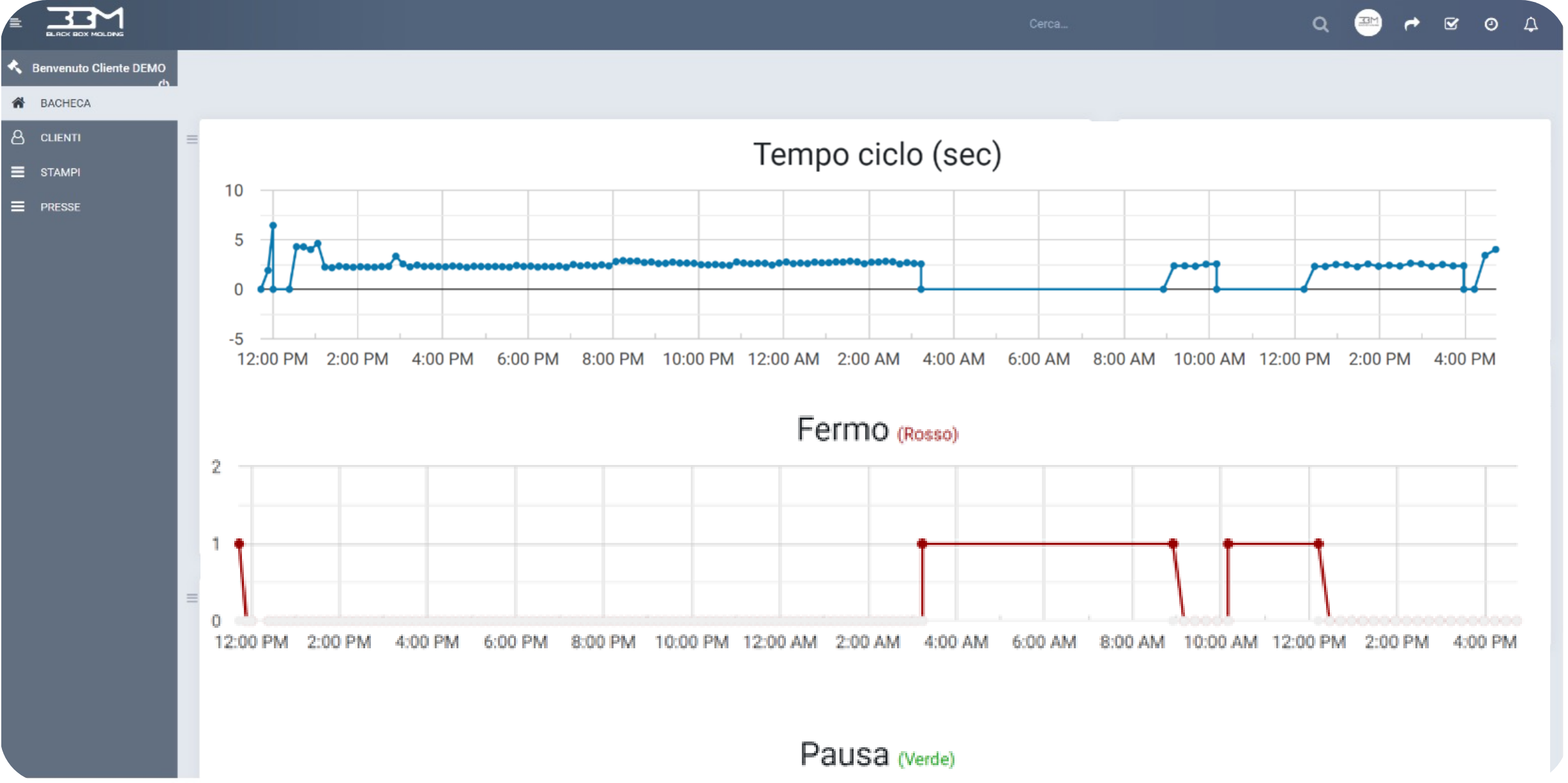

This device tracks the position and the travels of the molds in real-time, keeping record of cycles and progresses for the production plan. Moreover, BBMold supports order management and maintenance planning activities.

Who is BBMold for?

BBMold is the ideal solution for those who need to monitor the activity of their molds spread around different production sites without manual entries.

This device tracks the position and the travels of the molds in real-time, keeping record of cycles and progresses for the production plan. Moreover, BBMold supports order management and maintenance planning activities.

Any questions about BBMold?

In the following section, you could find the most frequent questions from our customers. If you do not find what you are looking for, fill in the form below and get in touch with us. Feel free to contact us for any questions!

Do you want to improve the productivity of your molds?

Monitor any single mold and adjust its performance in real-time!

Fill in the form below and get contacted!

©2024 TF Lab SRL | VAT number IT-03786170989 | Via Maestro Zanagnolo, 10L | 25065 Lumezzane BS IT | Transparency | Privacy Policy | Cookie Policy | Concept By Mr Keting

The BBMOLD brand is owned by TF Lab SRL

Do you want to improve the productivity of your molds?

Monitor any single mold and adjust its performance in real-time!

Fill in the form below and get contacted!

©2024 TF Lab SRL | VAT number IT-03786170989 | Via Maestro Zanagnolo, 10L | 25065 Lumezzane BS IT | Transparency | Privacy Policy | Cookie Policy | Concept By Mr Keting

The BBMOLD brand is owned by TF Lab SRL